Simple charger for lithium batteries. Charger circuit for lithium Li-Ion batteries. Lithium Ion Battery Chargers

Lithium batteries (Li-Io, Li-Po) are currently the most popular rechargeable sources of electrical energy. The lithium battery has a nominal voltage of 3.7 volts, which is indicated on the case. However, a 100% charged battery has a voltage of 4.2 V, and a discharged “to zero” - 2.5 V, there is no point in discharging the battery below 3 V, firstly, it deteriorates from this, and secondly, in the range from 3 to 2.5 Only a couple of percent of the energy is transferred to the battery. Thus, the operating voltage range is taken to be 3 - 4.2 Volts. You can watch my selection of tips for using and storing lithium batteries in this video.

There are two options for connecting batteries, serial and parallel.

With a series connection, the voltage on all batteries is summed up, when the load is connected, a current equal to the total current in the circuit flows from each battery, in general, the load resistance sets the discharge current. You must remember this from school. Now comes the fun part, the capacity. The capacity of the assembly with such a connection is good equal to the capacity of the battery with the smallest capacity. Let's assume that all batteries are 100% charged. Look, the discharge current is the same everywhere, and the battery with the smallest capacity will be discharged first, this is at least logical. And as soon as it is discharged, it will no longer be possible to load this assembly further. Yes, the rest of the batteries are still charged. But if we continue to remove the current, then our weak battery will start to over discharge and fail. That is, it is correct to assume that the capacity of a series-connected assembly is equal to the capacity of the smallest or most discharged battery. From here we conclude: firstly, you need to collect a serial battery from batteries of the same capacity, and secondly, before assembly, they must all be charged the same way, in other words, 100%. There is such a thing called BMS (Battery Monitoring System), it can monitor each battery in the battery, and as soon as one of them is discharged, it disconnects the entire battery from the load, this will be discussed below. Now with regard to charging such a battery. You need to charge it with a voltage equal to the sum of the maximum voltages on all batteries. For lithium, this is 4.2 volts. That is, we charge a battery of three with a voltage of 12.6 V. See what happens if the batteries are not the same. The battery with the smallest capacity will charge the fastest. But the rest are still not charged. And our poor battery will fry and recharge until the rest are charged. Overdischarge, I remind you, lithium also does not like very much and deteriorates. To avoid this, we recall the previous conclusion.

Let's move on to parallel connection. The capacity of such a battery is equal to the sum of the capacities of all the batteries included in it. The discharge current for each cell is equal to the total load current divided by the number of cells. That is, the more Akum in such an assembly, the more current it can deliver. An interesting thing happens with tension. If we collect batteries that have different voltages, that is, roughly speaking, charged to different percentages, then after connection they will begin to exchange energy until the voltage on all cells becomes the same. We conclude: before assembling the Akum, they must again be charged in the same way, otherwise, when connected, large currents will flow, and the discharged Akum will be damaged, and most likely it may even catch fire. In the process of discharging, the batteries also exchange energy, that is, if one of the cans has a smaller capacity, the rest will not allow it to discharge faster than themselves, that is, batteries with different capacities can be used in parallel assembly. The only exception is work at high currents. On different batteries under load, the voltage sags in different ways, and between the “strong” and “weak” Akum, the current will start to run, but we do not need this at all. And the same goes for charging. You can absolutely safely charge batteries of different capacities in parallel, that is, balancing is not needed, the assembly will balance itself.

In both cases considered, the charging current and the discharge current must be observed. The charging current for Li-Io should not exceed half the battery capacity in amperes (1000 mah battery - charge 0.5 A, battery 2 Ah, charge 1 A). The maximum discharge current is usually indicated in the datasheet (TTX) of the battery. For example: laptop 18650s and batteries from smartphones cannot be loaded with a current exceeding 2 battery capacities in Amperes (example: Akum for 2500 mah, which means that you need to take a maximum of 2.5 * 2 = 5 Amperes from it). But there are high-current batteries, where the discharge current is clearly indicated in the characteristics.

Features of charging batteries with Chinese modules

Standard commercially available charging and protection module for 20 rubles for lithium battery ( link to Aliexpress)

(positioned by the seller as a module for one 18650 cell) can and will charge any lithium battery regardless of shape, size and capacity to the correct voltage of 4.2 volts (voltage of a fully charged battery, to the eyeballs). Even if it's a huge 8000mah lithium package (of course, we are talking about one 3.6-3.7v cell). The module provides a charging current of 1 amp, this means that they can safely charge any battery with a capacity of 2000mah and above (2Ah, which means the charging current is half the capacity, 1A) and, accordingly, the charging time in hours will be equal to the battery capacity in amperes (in fact, a little more, one and a half to two hours for every 1000mah). By the way, the battery can be connected to the load already during charging.

Important! If you want to charge a battery with a smaller capacity (for example, one old 900mah can or a tiny 230mah lithium bag), then the charging current of 1A is a lot, it should be reduced. This is done by replacing the resistor R3 on the module according to the attached table. The resistor is optional smd, the most common one will do. Let me remind you that the charging current should be half of the battery capacity (or less, no big deal).

But if the seller says that this module is for one 18650 can, can they charge two cans? Or three? What if you need to assemble a capacious power bank from several batteries?

CAN! All lithium batteries can be connected in parallel (all pluses to pluses, all minuses to minuses), REGARDLESS OF CAPACITY. Batteries soldered in parallel maintain an operating voltage of 4.2v and their capacity is added. Even if you take one can at 3400mah and the second at 900, you get 4300. The batteries will work as a whole and will discharge in proportion to their capacity.

The voltage in a PARALLEL assembly is ALWAYS THE SAME ON ALL BATTERIES! And not a single battery can be physically discharged in an assembly earlier than others, the principle of communicating vessels works here. Those who argue the opposite and say that batteries with a lower capacity will discharge faster and die - they confuse it with SEQUENTIAL assembly, spit in their faces.

Important! Before connecting to each other, all batteries must have approximately the same voltage, so that at the moment of soldering, equalizing currents do not flow between them, they can be very large. Therefore, it is best to simply charge each battery separately before assembling. Of course, the charging time of the entire assembly will increase, since you are using the same 1A module. But you can parallelize two modules, getting a charging current of up to 2A (if your charger can give that much). To do this, connect with jumpers all the analogous terminals of the modules (except for Out- and B +, they are duplicated on the boards by other dimes, and will be connected anyway). Or you can buy a module ( link to Aliexpress), on which the microcircuits are already in parallel. This module is capable of charging with a current of 3 Amperes.

Sorry for the obvious, but people are still confused, so we have to discuss the difference between parallel and serial.

PARALLEL the connection (all pluses to pluses, all minuses to minuses) maintains the battery voltage of 4.2 volts, but increases the capacity by adding all the capacities together. All power banks use a parallel connection of several batteries. Such an assembly can still be charged from USB and the voltage rises to the output 5v with a step-up converter.

CONSECUTIVE the connection (each plus to minus of the subsequent battery) gives a multiple increase in the voltage of one charged 4.2v can (2s - 8.4v, 3s - 12.6v, and so on), but the capacity remains the same. If three 2000mah batteries are used, then the assembly capacity is 2000mah.

Important! It is believed that for sequential assembly it is sacred to use only batteries of the same capacity. In fact, this is not the case. You can use different ones, but then the battery capacity will be determined by the LOWEST capacity in the assembly. Add 3000 + 3000 + 800 - you get 800mah assembly. Then the specialists begin to crow, that then the less capacious battery will discharge faster and die. It doesn't matter! The main and truly sacred rule is that for consistent assembly it is always and absolutely necessary to use the BMS protection board for the required number of cans. It will determine the voltage on each cell and turn off the entire assembly if any discharges first. In the case of a bank for 800, it will be discharged, the BMS will disconnect the load from the battery, the discharge will stop and the residual charge of 2200mah on the remaining banks will no longer matter - you need to charge.

The BMS board, in contrast to the single charging module, IS NOT a CHARGER for sequential assembly. To charge you need configured source of the required voltage and current... Guyver made a video about this, so do not waste time, watch it, there it is about it as thoroughly as possible.

Can a daisy chain be charged by connecting multiple single charging modules?

In fact, with some assumptions, it is possible. For some homemade products, the scheme has proven itself using single modules, also connected in series, but EACH module needs its own SEPARATE POWER SUPPLY. If you charge 3s - take three phone chargers and connect each one to one module. When using one source - power short circuit, nothing works. Such a system also works as a protection of the assembly (but the modules are capable of delivering no more than 3 amperes) Or, simply charge the assembly in batches, connecting the module to each battery until it is fully charged.

Battery charge indicator

It is also an urgent problem - at least to know approximately how many percent of the charge remains on the battery so that it does not discharge at the most crucial moment.

For parallel assemblies at 4.2 volts, the most obvious solution would be to immediately purchase a ready-made powerbank board, which already has a display showing the percentage of charge. These percentages are not super-accurate, but they still help. The price of the issue is about 150-200 rubles, all are presented on Guyver's website. Even if you are collecting not a powerbank, but something else, this board is quite cheap and small to place it in a homemade product. Plus, it already has the function of charging and protecting batteries.

There are ready-made miniature indicators for one or several cans, 90-100r

Well, the cheapest and most popular method is to use an MT3608 step-up converter (30 rubles), tuned to 5-5.1v. Actually, if you make a power bank on any 5-volt converter, then you don't even need to buy anything. The revision consists in installing a red or green LED (other colors will work at a different output voltage, from 6V and above) through a 200-500 ohm current-limiting resistor between the output positive terminal (this will be a plus) and the input positive (for the LED it will turn out to be a minus). You are not mistaken, between two pluses! The fact is that when the converter is operating, a voltage difference is created between the pluses, +4.2 and + 5v give each other a voltage of 0.8v. When the battery is discharged, its voltage will drop, and the output from the converter is always stable, which means the difference will increase. And when the voltage on the bank is 3.2-3.4v, the difference will reach the required value to light the LED - it starts to show that it is time to charge.

How to measure the capacity of batteries?

We are already accustomed to the opinion that Aimax b6 is needed for measurement, but it costs money and is redundant for most radio amateurs. But there is a way to measure the capacity of a 1-2-3 can battery with sufficient accuracy and cheap - a simple USB tester.

A charger for lithium batteries in its structure and principle of operation is very similar to a charger for lead-acid batteries. Each lithium battery bank has a higher voltage rating. In addition, they are more sensitive to overvoltage and overcharging.

The jar is one life-giving element. It got its name from the similarity to cans for drinks. For lithium cells, the most common option is 18650. This number is easily deciphered. Thickness is indicated in millimeters - 18 and height - 65.

If other types of batteries allow for a greater run-up in the supplied voltage when charging, then for lithium batteries this indicator should be much more accurate. When the battery reaches a voltage of 4.2 volts, charging should stop, overvoltage is dangerous for them. A deviation from the norm of 0.05 volts is allowed.

The average charge time for lithium batteries is 3 hours. This is an average figure, yet each individual battery has its own value. The service life of lithium batteries depends on the quality of charging.

Long-term storage conditions

Advice. Store lithium-ion batteries correctly. If the device will not be used for a long time, it is better to remove the battery from it.

If a fully charged battery is left in storage, it may permanently lose some of its capacity. If a discharged battery is left in storage, it may no longer recover. This means that even trying to revive her, you can fail. Therefore, the optimal recommended charge for storing lithium cans is 30-50%.

Using original chargers

Some manufacturers indicate that the use of non-native Li-ion battery chargers may void the device warranty. The point is that a bad charger can destroy a battery cell. Lithium batteries can deteriorate due to incorrect voltage or incorrect damping at the end of charging. Therefore, using the original charger is always the best choice.

Danger of overcharging and full discharge

Due to the design of lithium batteries, it is not recommended to completely discharge or overcharge them.

For example, nickel-cadmium batteries have a memory effect. This means that the wrong charging mode results in a loss of capacity. The mode is considered incorrect when the battery is recharged, which is not completely discharged. If you start charging it in an incompletely discharged state, it may lose its capacity. Chargers for such batteries are manufactured with special operating modes, which first discharge the battery to the required level, then begin to recharge it.

Lithium batteries do not require such troublesome maintenance. They have no memory effect, but they are afraid of a complete discharge. Therefore, it is better to recharge them when the opportunity arises, without waiting for a full discharge. But recharging is also unacceptable for them. Therefore, it would be optimal not to allow a discharge below 15% and a charge of more than 90%. This will extend the battery life.

This only applies to batteries without protection. If the batteries have protection implemented on a separate board, then it cuts off the excess charge, if the discharge reaches the minimum level, then it turns off the device. Usually these are indicators of more than 4.2 Volts and 2.7 Volts, respectively.

Relation to temperature extremes

The operating temperature range for lithium batteries is small - from +5 to +25 degrees Celsius. Strong temperature changes are undesirable for their operation.

Overcharging can cause the battery temperature to rise and adversely affect its performance. Low temperatures also have a negative effect. It was noticed that in cold weather the batteries lose their charge faster and sit down, although in warm temperatures the device shows a full charge.

Features of lithium batteries

Li-ion batteries are very easy to use. With careful handling, they will last about 3-4 years. However, it is worth focusing on the fact that even if the batteries are not used, they slowly die. Therefore, it is not entirely reasonable to stock up on batteries for the device for future use. 2 years is normal production time. If more has passed, then these may be batteries that are already out of order.

Interesting. The most common 18650 can has an average of 3500mAh. The normal price for such a battery is $ 3-4. Therefore, manufacturers promising a 10,000 mAh Power bank for $ 3 are, to put it mildly, cheating. It's good if there is at least 3000 mAh.

How to properly charge a polymer battery

The polymer accumulator differs from the ionic one only in the internal consistency of the filler. Charging and operating guidelines apply to both types of these lithium batteries.

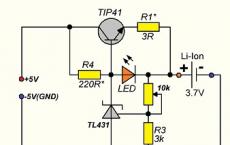

How to make a DIY lithium battery charger

Consider one of the simplest lithium-ion battery charger circuits. A homemade charging circuit is implemented on a microcircuit, which acts as a zener diode and a charge controller, and a transistor. The base of the transistor is connected to the control electrode of the microcircuit. Lithium batteries do not like overvoltage, therefore, the output must be set to the recommended voltage of 4.2 V. This can be achieved by adjusting the microcircuit with resistances R3 R4, which have values of 3 kOhm and 2.2 kOhm, respectively. They are connected to the first leg of the microcircuit. The regulation is set once and the voltage remains constant.

To be able to adjust the voltage at the output at the site of the resistor R, a potentiometer is installed. You need to make adjustments without load, that is, without the battery itself. With its help, you can accurately adjust the output voltage, equal to 4.2 V. Then, instead of a potentiometer, you can put a resistor of the resulting value.

Resistor R4 is used to open the base of the transistor. The rating of this resistance is 0.22 kOhm. When the battery is being charged, its voltage will rise. From this, the control electrode on the transistor will increase the emitter-collector resistance. This, in turn, will reduce the current going to the battery.

You also need to adjust the charging current. For this, resistances R1 are used. Without this resistor, the LED will not light up, it is responsible for indicating the charging process. Depending on the required current, select a resistor with a nominal value of 3 to 8 ohms.

How to choose a battery

Special attention should be paid to battery manufacturers. There are proven brands and some unknown analogues. Sometimes unscrupulous manufacturers can sell a product that is 3 times or more below the declared characteristics.

Note! The brands that have gained popularity include Panasonic, Sony, Sanyo, Samsung.

Buying lithium batteries shouldn't be too much of a problem. You can buy them from local electronics stores, online retailers, or order directly from China. You should not chase cheapness. A good battery cannot be very cheap. Some manufacturers supply high-quality cans, but poor power boards. This will inevitably lead to the death of the battery.

Video

Putting together a simple lithium-ion battery charger, practically out of junk.

I have accumulated a large number of batteries from laptop batteries, 18650 format. Thinking how to charge them, I decided not to bother with Chinese modules, and I had run out of them by that time. I decided to put together two schemes. Current sensor and BMS board from mobile phone battery. Tested in practice. Although the circuit is primitive, it works and successfully, not a single battery was damaged.

Charger circuit

Materials and tools

- USB cable;

- crocodiles;

- BMS protection board;

- plastic egg from kinder;

- two LEDs of different colors;

- transistor kt361;

- resistors for 470 and 22 ohms;

- two-watt resistor 2.2 ohm;

- one diode IN4148;

- instruments.

Making a charger

Disassemble the USB cable and remove the connector. I have it from some kind of aipad.

We solder the wires to the crocodiles.

We make the deep part of the plastic kinder heavier, I filled the M6 nut with hot melt glue.

We solder our simple schematic. Everything was done by surface mounting and soldered on the BMS board. I used a dual LED, but you can use two single-color ones. The transistor was dropped from the old Soviet radio equipment.

We pass the wires into the hole in the second, shallow, half of the plastic kinder. We solder the circuit.

We stuff everything compactly into a plastic egg. We make a hole for the LED.

We connect to the USB port of a PC or Chinese charger, they still have little current.

Lights up orange during charging. Those. Both LEDs are on.

When the charge is over, the green one is on, the one that is connected through the diode IN4148.

You can check the circuit by disconnecting from the battery, the green LED will light up, indicating the end of the charge.

Lithium-ion batteries are not as picky as their nickel-metal hydride counterparts, but they still require some maintenance. Adhering to five simple rules, you can not only extend the life cycle of lithium-ion rechargeable batteries, but also increase the operating time of mobile devices without recharging.

Do not allow full discharge. Lithium-ion batteries do not have a so-called memory effect, so they can and, moreover, need to be charged without waiting for discharge to zero. Many manufacturers calculate the life of a lithium-ion battery as a number of full discharge cycles (up to 0%). For quality batteries, this is 400-600 cycles... To extend the life of your lithium-ion battery, charge your phone more often. Optimally, as soon as the battery charge drops below the 10-20 percent mark, you can put the phone on charge. This will increase the number of discharge cycles to 1000-1100

.

Experts describe this process by such an indicator as Depth Of Discharge. If your phone is up to 20% discharged, then the Depth of Discharge is 80%. The table below shows the relationship between the number of discharge cycles of a lithium-ion battery and the Depth of Discharge:

Discharge every 3 months. A full charge for a long time is just as harmful to lithium-ion batteries as being constantly discharged to zero.

Due to the extremely unstable charging process (we often charge the phone as necessary, and where it works, from USB, from an outlet, from an external battery, etc.), experts recommend completely discharging the battery once every 3 months and then charging it to 100% and holding it on charge 8-12 hours. This helps to reset the so-called high and low battery charge flags. You can read more about this.

Store partially charged... The best condition for long-term storage of a lithium-ion battery is between 30 and 50 percent charge at 15 ° C. If the battery is left fully charged, its capacity will decrease significantly over time. But the battery, which has been gathering dust on the shelf for a long time discharged to zero, most likely is no longer a tenant - it's time to send it for recycling.

The table below shows how much capacity remains in a lithium-ion battery depending on storage temperature and charge level when stored for 1 year.

Use the original charger. Few people know that in most cases the charger is built directly into mobile devices, and an external power adapter only lowers the voltage and rectifies the current of the household power supply, that is, it does not directly affect the battery. Some gadgets, such as digital cameras, do not have a built-in charger, and therefore their lithium-ion batteries are inserted into an external “charger”. This is where the use of an external charger of questionable quality instead of the original one can negatively affect the performance of the battery.

Do not overheat. Well, the worst enemy of lithium-ion batteries is high temperature - they cannot stand overheating at all. Therefore, do not expose mobile devices to direct sunlight or leave them in the immediate vicinity of heat sources such as electric heaters. Maximum permissible temperatures at which lithium-ion batteries can be used: from –40 ° C to + 50 ° C

Also, you can see

Li-ion batteries of the 18650 type of various capacities are now very widespread. With their purchase, the problem of charging arises and it is obligatory in accordance with the technical requirements for the charging process. Some of these requirements are:

- charging with a stable current;

- voltage stabilization mode;

- indication of the end of charging;

- not exceeding the permissible temperature while charging the battery.

We would like to draw your attention to an easy-to-manufacture and commissioning scheme for the charger of Li-ion batteries, which has proven itself in operation.

The circuit is a current and voltage stabilizer. Until the voltage on the battery during charging reaches the level Ustab. = (R7 / R5 + 1) * Uref (Uref reference voltage TL431 = 2.5V), TL431 is in the closed state, and the circuit works as a current stabilizer. Istab. = 0.6 / R2 (0.6 is the opening voltage of the KT816V transistor). As soon as the voltage on the battery reaches Ustab., The circuit switches to the voltage stabilization mode. For a Li-ion battery, this value is 4.2V. When the voltage on the battery reaches 4.2V, a yellow LED starts to glow, signaling that the battery is 80-90% charged. The charging current drops to 7 ... 8mA. Leave the battery in this state for 10-15 hours to gain full capacity.

A little about the purpose of the circuit elements.

LED1 - blue, lights up when the battery (AK) is installed in the charging box with the charger not powered. When the AC voltage is less than 3V, LED1 does not light up.

LED2 is yellow. Serves to indicate the end of the AK charging process. When an uncharged AK is installed in the box, LED2 does not light up. If it is lit, then it means that a charged AK is inserted into the box (when the charger is not powered).

R2 - limits the charging current of the AK.

R5, R7 - are used to set a voltage of 4.2V at the contacts of the charging box before installing a battery in it (you can use any one).

All parts of the charger, except for the transistor, are installed on the printed circuit board from the side of the printed conductors:

Board option for those who are not lazy to drill holes in fiberglass:

The transistor is equipped with a small heat sink. During charging, the transistor heats up to 40 ° C. Resistor R2 also heats up, so it is better to install two 10 ohms in parallel to reduce heating.

The voltage of the power supply for charging one battery is approximately 5V DC. If it is necessary to charge several batteries at once, the power supply voltage is selected so that it is 4.2V on each unit. The power of the power supply unit is selected from the value of the charging current for each battery. You can use a switching power supply. The dimensions of the charger will be smaller.

Setting up the charger is straightforward. Without inserting the battery, we supply power to the circuit. Both LEDs should be on. Next, we measure the voltage at the contacts of the charging box. If it is 4.2V, you are in luck and the setup is almost complete. If the voltage is more or less than 4.2V, turn off the power, instead of resistor R5 or R7, we solder a variable multiturn resistor 10k and precisely set the voltage to 4.2V at the box contacts. Having measured the value of the resulting resistance of the tuning resistor, we select the same constant and solder it into the circuit. Once again we check the voltage at the contacts of the charging box. We check the value of the charging current with an ammeter at the contacts of the charging box, without inserting the battery. By selecting the value of the resistor R2, you can set the desired charging current. We are not carried away with large currents, the battery may warm up, which is categorically unacceptable. Due to overheating, the capacity of Li-ion batteries decreases and does not recover.

The batteries are best charged one at a time. If it is necessary to charge several batteries at the same time, you can connect the blocks in series according to this scheme.

In this scheme, each battery is charged separately. The voltage at the end of charging on each AK will be 4.2V, and the charging current will be 0.5A. When charging seven batteries simultaneously, for example, the voltage of the power source should be 4.2V * 7 = 29.5V. The power source power is determined by the value of the charging current 0.5A for each AK, i.e. approximately 40W.

Photo of the finished device.